New Plate Beveling Service Coming Soon

New Plate Beveling Service Coming Soon

Precision Bevel, LLC will be commissioning our new FasRapid LGA 3000 II Beveling Machine as we offer plate beveling as a service in early September 2019 from our new facility in Burlington, Kentucky. This type of plate beveler is the first and only machine of its kind in North America.

This high-performance beveling machine is designed for high volume plate beveling. The machine uses an abrasive belt that can process a variety of metals including carbon steel, stainless steel, and specialty metals with high alloy content including Nickel (Ni), Titanium (Ti), and Chromium (Cr).

Accurate Bevel Facing

Accurate Bevel Facing

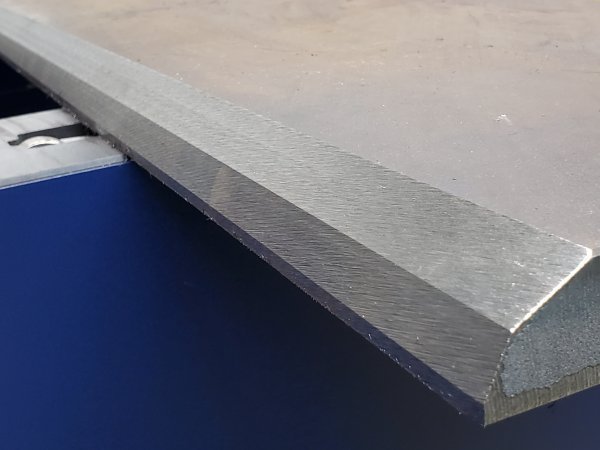

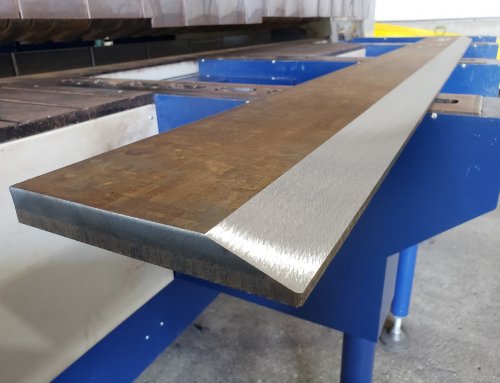

We can produce an accurate bevel face of up to 4″ plus. The speed and efficiency of this machine allows us to bevel metal better, faster and cheaper for our clients.

Why Use a Plate Beveling Service?

Why Use a Plate Beveling Service?

Since this machine utilizes a high velocity grinding belt, the concept is much more material agnostic than conventional beveling methods. We can now process carbon steel, stainless steel, nickel alloys and armor plate. The CNC controlled grinding unit allows bevel angles between 0 [facing] and 80 degrees. The grinding process is also much more economical than other competing processes. The FasRapid LGA 3000 II Beveling Machine can handle up to 10 foot long pieces in one clamping. Longer pieces can also be processed by indexing them through the machine allowing for unlimited beveling possibilities.

The FasRapid machine design pneumatically clamps metal plate onto a support table holding customer projects firmly in place. The ceramic grinding belt, which both oscillates to sustain grinding belt life and moves on a rail system, bevels the plate in one or more passes. This beveling machine offers the ability to apply top and bottom bevels. The control unit can be operated manually for unique projects. Automatic settings storing custom chamfer angles and depths allow us to efficiently process quantity orders quickly and efficiently.